Powered by Prescient AI Software

The military uses Prescient software in field analysis programs for the U.S. Marines, the software can process samples in the field in under 10 minutes. Prescient software provides simplified reports for in-field maintenance recommendations and provides upstream detailed analysis for fleet management. Using Prescient’s cloud-based data, upstream management can schedule in-field tests when anomalies are detected from analysis across the fleet are discovered. Prescient keeps your equipment performing effectively and efficiently. Fluid, vibration and ultrasonic in-field condition evaluation and monitoring for industry. Contact us to learn more.

Utilizing A Commercial Application of Military Technology

- Lube analysis part of DoD’s effort to reduce costs and improve equipment reliability

- Provides data about lube and equipment condition

- Detailed reports explain the meaning of data

- DoD studies have confirmed that Fluidology™ can:

- Detect early stage mechanical problems

- Lower costs by extending lube changes

Lube condition

- Information on viscosity, contaminants, general lubricant condition

- Does lubricant need to be changed or not

Component condition problems such as…

- Abnormal wear

- High wear metal counts in a sample (iron, aluminum, copper, lead)

- Air system leaks

- High silicon value in a sample

- Head gasket leaks, cracked blocks

- Glycol and / or water in the lube

- Combustion problems

- Soot in the lube of a diesel engine

- Leaking seals

- Water or high particle count in a transmission or gear box

- Contaminated hydraulic systems

- High particle counts

What does Advanced Lubricant Analysis reveal?

- First, lubricant analysis determines whether the lubricant itself is capable of doing its job

- For example, a lubricant whose viscosity is too low will not provide suficient lubricity and minimize metal-to-metal contact

- A viscosity too high often means oxidation, a chemistry change, has set in, also affecting lubricity

- Similarly, if a lubricant is contaminated with glycol (e.g., anti-freeze) or with too much water, the lubricant will not provide good protection.

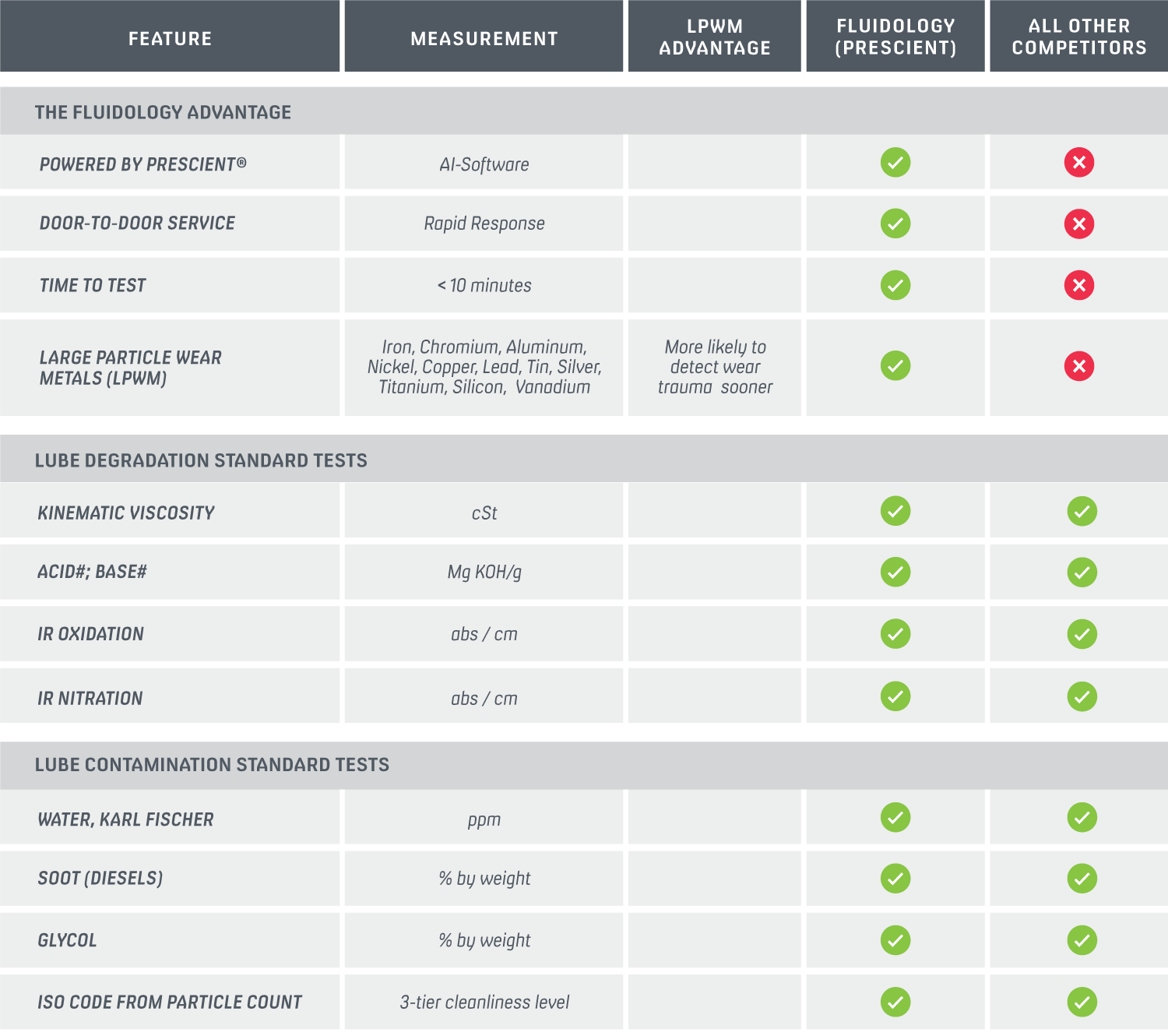

- This table lists the lubricant properties that we evaluate.

Lubricant Property |

Notes |

Viscosity |

If too low or too high the (asset, machine, component) will not be fully protected |

Water |

Modest amounts of water may be acceptable, but too much water is bad |

Glycol |

Any glycol in the lube is bad for an engine. Bearing seizure can result in short order |

Soot |

Found in diesel engines. High values suggest combustion problems or restricted air intake, or worn rings, etc. |

Acid #

|

A basic chemistry test for acid content and assessing lube quality and performance |

Base # |

A basic chemistry test for reserve alkalinity in the lube, essential when sulfur in the fuel might be present |

Particle count |

A measure of a lubricant’s cleanliness |

Second, lubricant analysis provides information about the mechanical condition of a component.

- As components wear, they shed particles such as iron, copper, aluminum and lead into the lubricant.

- While wear is generally unavoidable in mechanical devices, some kinds of wear lead to catastrophic breakdowns.

- Small particles (e.g., 4 microns or less) indicate normal wear while large particles (e.g., greater than 4 microns) suggest that the component is wearing abnormally. As a reference point, consider that a typical human hair is 50 microns wide.

Table 2: Elemental Analysis Attributes Assessed using

Lubricant Property |

Notes |

| Iron (Fe) | One of “Big 4” wear metals – most frequently present – often trended, in addition to limits |

| Aluminum (Al) | One of “Big 4” wear metals – frequently present – often trended, in addition to limits |

| Copper (Cu) | One of “Big 4” wear metals – frequently present – often trended, in addition to limits |

| Lead (Pb) | One of “Big 4” wear metals – frequently present – often trended, in addition to limits |

| Chromium (Cr) | Clarifying as to a particular part in a machine – always set to limits, occasionally trended if persistent |

| Tin (Sn) | Clarifying as to a particular part in a machine – always set to limits, occasionally trended if persistent |

| Nickel (Ni) | Clarifying as to a particular part in a machine – always set to limits, occasionally trended if persistent |

| Silver (Ag) | Clarifying as to a particular part in a machine – always set to limits, occasionally trended if persistent |

| Iron (Fe) | Clarifying as to a particular part in a machine – always set to limits, occasionally trended if persistent |

| Titanium (Ti) | Clarifying as to a particular part in a machine – always set to limits, occasionally trended if persistent |